Tech Article

Published on:

As the use of autonomous systems continues to grow, the importance of their ease of integration cannot be overstated. This refers to how seamlessly a system can be integrated into a vehicle or platform, both physically and electronically.

One of the most challenging aspects of integration is incorporating key components like an inertial navigation system (INS). These systems require accurate calibration and alignment to function properly, which can be time-consuming. Even experienced engineers can find INS integration to be a challenging task, let alone those new to navigation technology.

That’s why, when choosing an INS, it is crucial to consider ease of integration alongside factors like performance, features and cost. A system that is easy to integrate provides numerous advantages, including reduced setup time, lower integration costs, hassle-free maintenance and quicker deployment.

Moreover, ease of integration directly impacts the accuracy and reliability of an INS. Poorly integrated systems can suffer from errors, drift and other issues that can negatively affect their performance.

To ensure a smooth integration experience, comprehensive documentation and reliable technical support are also essential. This includes having detailed installation instructions, troubleshooting guides, and access to expert assistance for any issues that may arise during or after installation.

When integrating an INS, it is essential to consider hardware compatibility. Most manufacturers understand this and ensure universal compatibility by using industry-standard interfaces and easily installable form factors, eliminating the need for major modifications. These interfaces, such as Ethernet, CAN, RS-232, RS-422 and general-purpose IO cables, not only meet essential technical requirements, they also provide high performance and minimize signal loss. Some manufacturers will offer unterminated cable options for bespoke solutions.

These interfaces allow users to integrate additional peripherals, sensors and data formats, such as odometers, wheel encoders, external RTK GNSS systems, NMEA inputs and outputs, and event triggers. To bridge any compatibility gaps, manufacturers may also offer adapters, cables and accessories to ensure their systems are compatible with hardware from other manufacturers.

In applications demanding heavy-duty performance, the electrical components for INS solutions must be durable and reliable, especially in extreme climates and challenging environments. One key aspect to consider is the ingress protection (IP) rating, which determines the level of defense against dust and water spray. High ratings, like IP67, offer the highest levels of protection.

When choosing an INS, it’s important to consider size, weight and power (SWaP) requirements. These aspects have a significant impact on the mechanical, electrical and power performance of the final system.

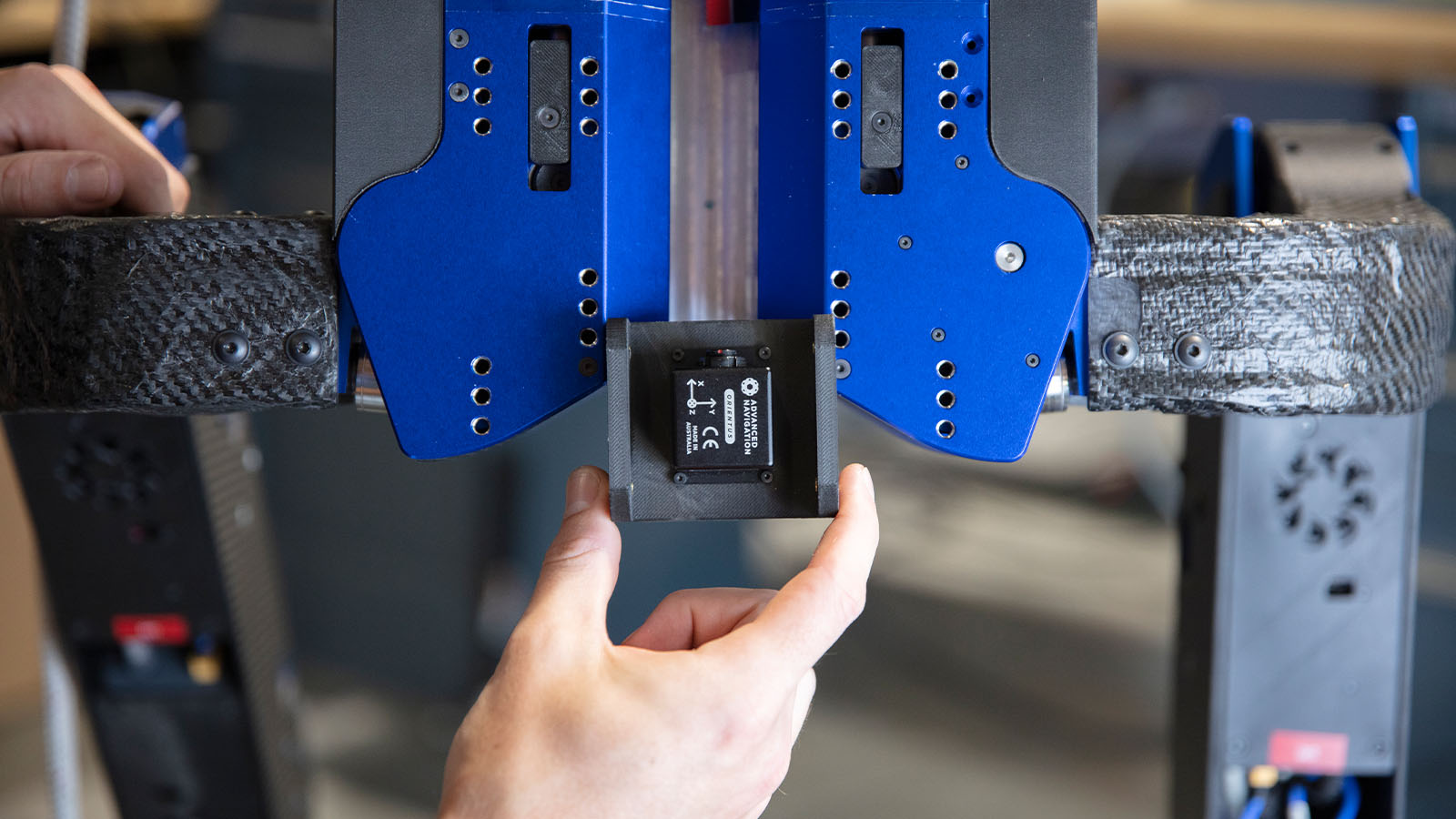

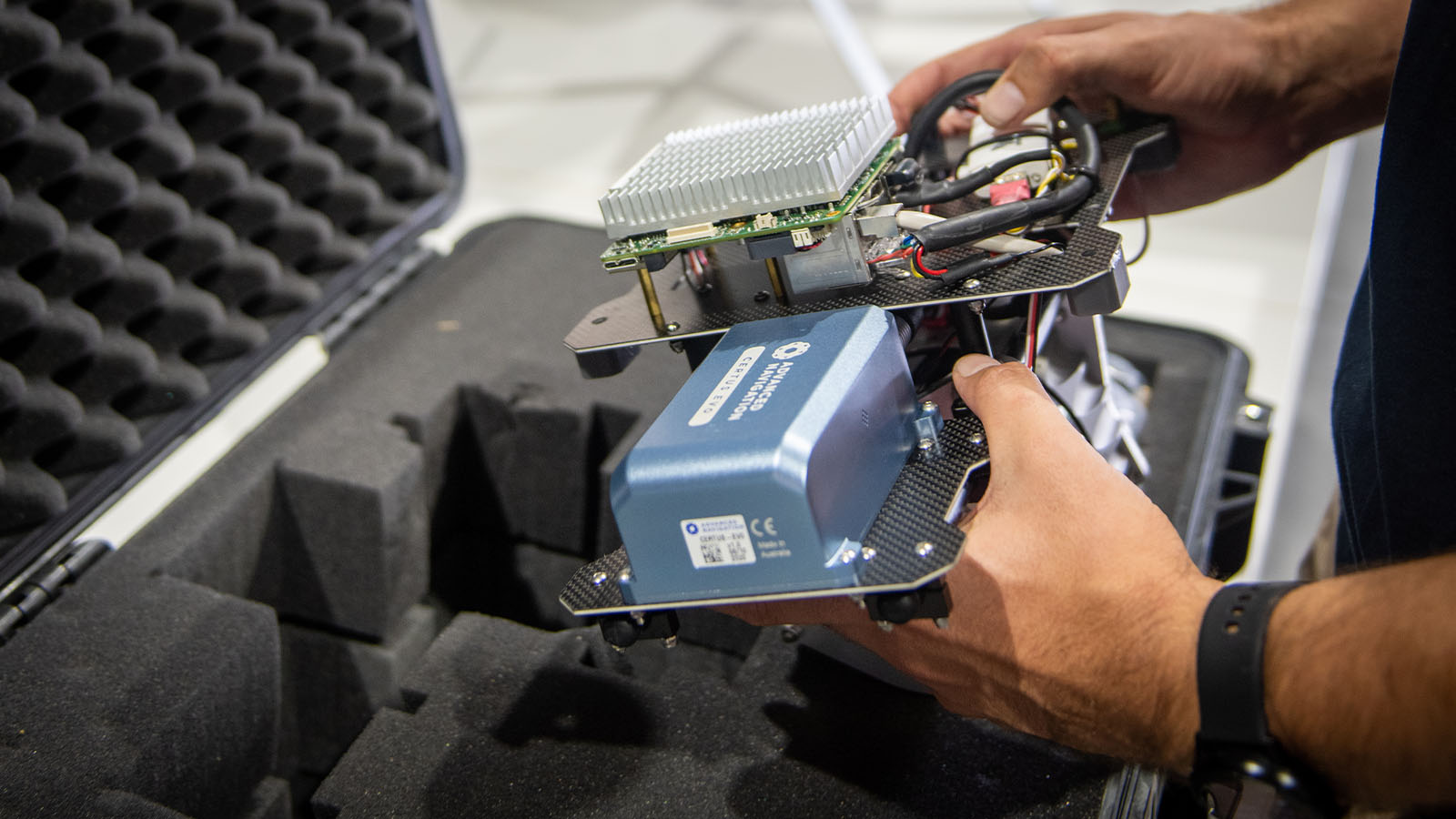

Size and weight are crucial factors, especially for users retrofitting an INS into older vehicles or working in small spaces with weight restrictions. Compact and lightweight INS systems are essential for applications like drones, as they can enhance flight stability, fuel efficiency and range. Similarly, low power consumption can help extend mission times and reduce the size or weight of the onboard power source, improving the overall capability of the platform.

For those seeking further customization, some INS manufacturers offer their solutions in different forms, including as an OEM (original equipment manufacturer) option with a PCB (printed circuit board) and standard connectors. This option is particularly valuable in applications where space and weight are at a premium.

Seamless integration between system components relies on having the right communication protocols in place. Just like hardware, most systems will be designed to be protocol-agnostic, allowing them to support various industry communication protocols. This versatility enables interoperability with diverse hardware setups.

The most common industry standard protocols include NMEA 0183, NMEA 2000 (primarily used for marine vessels) and Simrad. These protocols play a crucial role in ensuring smooth communication and compatibility.

Demanding applications require precise control and tight system integration, it can be advantageous to have an INS device manufacturer that offers their own comprehensive and open I/O protocol.

The Advanced Navigation Packet Protocol (ANPP), for example, is a proprietary binary protocol well regarded for its robust error checking. It is consistently used across all Advanced Navigation products and is particularly suitable for users who require precise control over their system configuration. ANPP seamlessly integrates with a variety of hardware components, simplifying upgrades or swaps between solutions.

For seamless installation and detailed performance analysis, INS solutions typically come included with hardware evaluation kits and software development kits (SDKs).

The majority of INS systems can be controlled, monitored and configured through a web-based graphical user interface (GUI). These interfaces are accessible through most web browsers and will provide real-time information on position and attitude, sensor information, data logging and NTRIP Client features.

Additionally, user interfaces will offer a wide range of configuration options for customizing the INS system to meet unique project requirements. Needless to say, the more intuitive and easy-to-use the interface, the easier it will be to set up and customize INS systems.

A reliable INS manufacturer understands the importance of supporting their customers from the start. They work closely with customers to provide all necessary documentation, training and ongoing support.

They should also be able to help customers choose the most appropriate solution for any given need and ensure compatibility with the required hardware and software. Upon choosing a solution, customers can then expect to receive detailed documentation and user guides covering everything from hardware setup to integration problems.

In an ideal world, manufacturers will also have specialized support engineers with extensive product knowledge, offering free technical support and troubleshooting through various channels. These engineers should also be accessible 24/7 to promptly address customer inquiries and efficiently resolve any issues that may arise.

Integrating navigational systems requires compliance with international regulations and requirements. Companies should research the regulations for their target market and ensure that their navigation system meets all requirements. Consider the following:

It is crucial not to underestimate the significance of availability and prompt delivery when choosing an INS. It is not uncommon for manufacturers and their suppliers to have long lead times of 6-12 months. It is therefore crucial to evaluate the manufacturer’s ability to deliver on time in order to ensure seamless operations. Neglecting this aspect could result in delays or order cancellations.

When it comes to choosing an INS solution or partner, it’s crucial to think carefully about the integration process. The key is to find a provider that values universal compatibility, comprehensive documentation, reliable technical support, customizable options and adherence to industry standards. These are the key factors that will make the integration experience seamless.

With the right INS solution and provider, users can simplify the integration process, eliminating the need for specialized knowledge or expensive technical assistance. This not only saves time and resources, it also guarantees long-term operational success.

20 May 2025

Go to Article

30 March 2025

Go to Article