Case Study

Published on:

Tamboritha, established in 1995, is a leading provider of subsea inspection and ROV services. Based in Melbourne, Australia, with operations extending across the Asia-Pacific region, Tamboritha is renowned for delivering safe, efficient and cost-effective solutions. With extensive experience in offshore oil and gas, renewables and defense industries, their team of expert professionals is adept at handling the unique challenges presented by deep underwater environments.

Offshore inspections and oil and gas operations come with their own set of challenges. When working in deep sea environments, the equipment used needs to be reliable and rugged enough to handle conditions that are severe and unpredictable. When tools fail or provide inaccurate data, it can lead to costly downtime, especially given the remote nature of these sites where quick fixes are rarely an option.

Tamboritha has experienced these challenges firsthand. In extreme environments, their fluxgate compass, prone to magnetic interference, often threw off critical tasks that required precise navigation. These disruptions didn’t just slow them down, they created real risks and setbacks. Recognizing the need for a more dependable navigation solution, Tamboritha sought underwater navigation equipment that could maintain stable and accurate orientation in high magnetic interference environments.

A key challenge that required pinpoint precision was a critical subsea drilling operation off the coast of Northern Territory, Australia. At a depth of 1,200 meters in black water conditions, Tamboritha’s task was to precisely place a 30-inch well conductor into a seabed drill slot.

“Positioning a conductor in pitch-black water is no easy feat,” Tamboritha Managing Director Wayne Ham noted. “In these conditions, typical visual methods are useless. Everything relies on technology like multi-beam sonar for object placement.”

This wasn’t just any routine task; it was part of a CO2 sequestration effort, crucial for meeting environmental expectations, Ham further explains: “As part of their policies, oil and gas companies must either buy large plots of land for trees or bury it in the seabed.”

Tamboritha had previously rented their subsea navigation system for similar tasks, however, due to the growing demand for such operations and having an ownership policy, they decided to invest in their own equipment.

Adding to these technical challenges was the project’s tight deadline, with only a few weeks allocated for completion. This meant the chosen navigation system had to meet stringent technical specifications while being rapidly delivered and integrated to keep the project on schedule.

After evaluating the leading options in the market, Tamboritha chose Advanced Navigation’s Boreas A70. The system stood out for its exceptional performance in challenging environments, delivering stable and precise orientation. Another key reason was due to Advanced Navigation having the shortest lead times in the industry, with the ability to provide products against stringent timelines.

“It’s been robust. It’s been reliable,” Ham said.

Other key reasons include:

Tamboritha was particularly impressed with the clear communication Advanced Navigation provided, as Ham points out: “Our IT guy looked at all of the responses from Advanced Navigation’s engineers and understood all the details.”

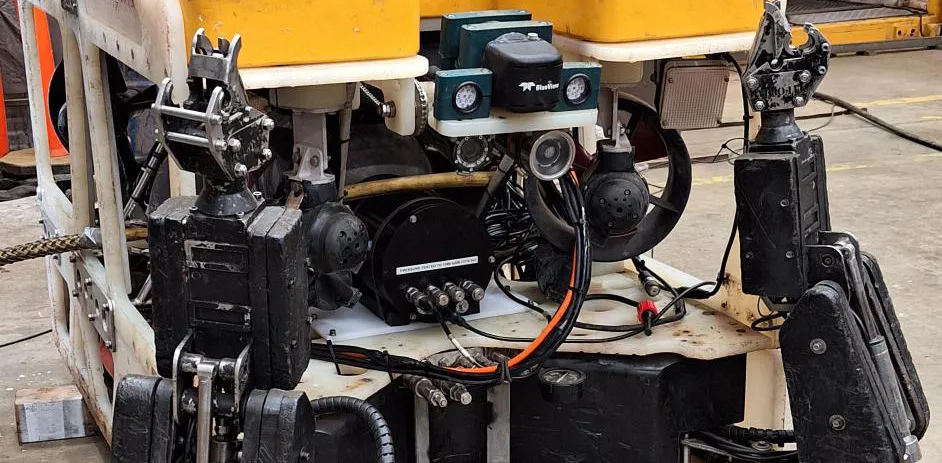

Ham explained, “The Saab Cougar XT isn’t inherently fiber optic ready or plug-and-play, so we designed one of the tooling pods specifically for third-party equipment like the A70, making it possible to fit the system seamlessly into the ROV.”

The integration process also involved configuring Ethernet connectivity for real-time data streaming and ensuring compatibility between the Boreas A70 and the ROV’s multi-beam sonar system. Advanced Navigation’s dedicated support was exceptional in helping streamline setup, enabling the Boreas A70 to function flawlessly alongside the existing equipment. This assisted integration was critical for Tamboritha to meet the project’s tight project deadlines.

Tamboritha also praised the Boreas A70’s reliability, especially its ability to handle quick power downs and reboots without losing position. This meant the ROV could operate continuously without interruption.

“You can do quick power downs and power backups, and it doesn’t phase it. It holds its position and reboots straight in.”

Tamboritha Managing Director Wayne Ham

Seaeye Cougar XT (Light Work Class ROV)

The integration of Boreas A70 has significantly enhanced Tamboritha’s operations, equipping their work-class ROVs with the precision, reliability and confidence needed to tackle complex subsea operations. In high-stakes operations like placing well conductors in the deep ocean under zero-visibility conditions, having stable and precise heading is needed to ensure correct infrastructure placement and ensuring its integrity. This is important as any operational mistakes can escalate and blow out costs and cause project delays, not to mention having environmental impacts.

By integrating Boreas A70, Tamboritha has strengthened its position as a key service provider in the industry, opening lucrative doors for the company to take on more complex subsea operations and meet growing demand for precision underwater infrastructure projects.

So far, Boreas’ quick integration and reliable performance, coupled with Advanced Navigation’s exceptional support, have enabled Tamboritha to deliver projects on time and within budget, building up their reputation as a trusted partner in the tight-knit subsea industry.

For Tamboritha, integrating the Boreas A70 INS into their work-class ROV operations was more than a technological upgrade for their work-class ROV; it has allowed them to accept new client requests and opportunities that they were not able to do before.

“Our experience with the Boreas A70 underscores how crucial having the right navigation technology can be. The A70 delivers the precision, resilience and confidence we need for challenging tasks in zero-visibility underwater environments,” Ham said.

“The best thing about Advanced Navigation? It’s backup and support.”

Wayne Ham said.

The Boreas A series combines cutting-edge Fiber Optic Gyroscope (FOG) technology with closed-loop accelerometers, which are coupled in a sophisticated fusion algorithm to deliver accurate and reliable orientation. The system features ultra-fast gyrocompassing, acquiring and maintaining an accurate heading under all conditions with no reliance on GNSS.